Machining

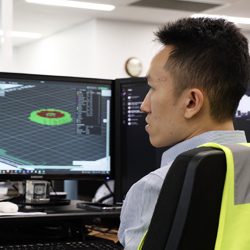

At Malcolm Thompson Pumps, innovation meets precision in our

state-of-the-art machine shop. Housing cutting-edge technology and staffed by industry veterans, our facility is your trusted partner for machining solutions that surpass expectations.

Whether you’re facing the simplest or the most intricate machining challenges, our machine shop is geared to handle a diverse range of high-precision components. Be it a unique custom part crafted from a highly engineered alloy or a high-volume component demanding unparalleled accuracy and repeatability, our commitment to excellence sets us apart.

What sets us apart is not just the quality of our finishes but the assurance of a superior standard. Our skilled team ensures that  each project,from intricate one-of-a-kind pieces to high-volume components, receives the meticulous attention it deserves.

each project,from intricate one-of-a-kind pieces to high-volume components, receives the meticulous attention it deserves.

The scale of our workshop positions us as leaders in the industry. Our substantial investment in a comprehensive range of machinery enables us to tailor our services to meet the specific needs of our customers.

Our cutting-edge offerings include:

- State-of-the-art CNC Machinery

- Multi-Function CNC Machines

- CNC Vertical Turning

- Component Strip and Assessment

At Malcolm Thompson Pumps, our commitment to quality, precision, and innovation makes us the go-to choice for those seeking machining solutions that stand above the rest. Trust us to be your partner in excellence as we continue to lead the way in the industry.

Experience the Malcolm Thompson Pumps advantage with our comprehensive machining services, delivering a host of benefits to our valued customers:

-

- Cost-Effective Solutions: Our commitment to efficiency ensures that you receive top-notch machining solutions without breaking the bank. We optimise our processes to provide cost-effective options without compromising on quality.

- Fast Turnaround: We understand that time can be crucial, which is why our streamlined processes guarantee swift turnaround times. Whether you require a custom component or a high-volume order, our efficiency ensures that your project is completed promptly.

- Design Services: Partner with us from concept to creation. Our experienced team offers design services to bring your ideas to life. We collaborate closely with you to understand your vision, ensuring the end result meets and exceeds your expectations.

- Customised Solutions: Recognising that every project is unique, we specialise in tailoring solutions to your specific needs. Whether it’s a one-of-a-kind custom part or a complex project requiring personalised attention,our team is dedicated to delivering solutions that match your requirements.

- Strict Adherence to Quality Standards: Quality is non-negotiable at Malcolm Thompson Pumps. Our machining services are conducted with precision and adhere to the strictest quality assurance standards. Trust us to deliver excellence in every component we produce.

At Malcolm Thompson Pumps, we don’t just offer machining services; we provide a partnership dedicated to cost-effective, timely, and customised solutions, all while upholding the highest standards of quality assurance. Your satisfaction is our priority.

Okuma MA600 HB 4-axis Horizontal Machining Centre with Pallet Changer

State-of-the-Art Equipment

At Malcolm Thompson Pumps, our commitment to innovation is reflected in our cutting-edge equipment lineup. In recent years, our substantial growth has empowered us to make significant investments in our facilities, ensuring we stay at the pinnacle of technology. Our state-of-the-art equipment includes:

State-of-the-Art Machine Shop:

Experience precision like never before in our advanced machine shop equipped with the latest technology. Our facility boasts a 4-Axis CNC Horizontal Machining Centre, consisting of:

Okuma MA600 Space Centre

- Two Pallet Changers for Efficient Production Setup

- Impressive Travel Dimensions: 600 X 600 X 400 mm

- High-Speed Machining Capability at 12000 RPM

Okuma Genos L300eMy X 1000 CNC Lathe

Okuma L3000EX Turn-Mill

- Max. Turning Diameter: 410 mm

- Turning Length between centres: 1000 mm

- Programmable Tailstock

- Axial and Radial Live Milling tool heads

Multi-Function CNC Machines:

Empower your projects with our versatile Okuma LB3000e and Okuma L3000Ex Turn-Mill machines, both equipped with Live Tooling. Key specifications include:

- Machining Size: 300mm Diameter X 1070mm Length Between Centres

- Y-Axis Movement (100mm) for Milling

CNC Vertical Turning Lathe featuring Live Tooling

CNC Vertical Turning:

Elevate your machining requirements with the Okuma V920Ex VTL, a CNC Vertical Turning Lathe featuring Live Tooling.

Key specifications include:

Machining Size: 920mm Diameter X 860mm

Manual Machines:

Dive into traditional craftsmanship with our manual machines,delivering precision and reliability:

Lathe:

Machining Size: 300mm Diameter

1070mm Length Between Centres with Steady Rest

Radial Drill:

50mm Drill Size

1600mm Arm Travel

Vertical Milling:

Machining Size: (Specify the dimensions)

Broaching:

(Specify details)

TM-33130HDX – Heavy Duty Centre Lathe

Radial Drill Machine

Vertical Milling Machine

At Malcolm Thompson Pumps, we don’t just meet industry standards; we set them. Our state-of-the-art equipment ensures precision, efficiency, and unmatched capabilities for your machining needs.Trust us to deliver excellence, driven by the latest technology and the expertise of our skilled team. Your journey to superior machining starts here.