Dewatering Pump Packages

At MTP, we are experts in designing dewatering pump packages for removing ground and surface water from mine sites, construction sites, flooded sites and bore holes.

Australian designed and manufactured, our dewatering units are utilised across a large range of industries and are suited to a variety of applications including mine dewatering, process water supply, water cart filling, dust suppression, evaporation projects, flood recovery and many more.

Our Dewatering Pump Package range includes:

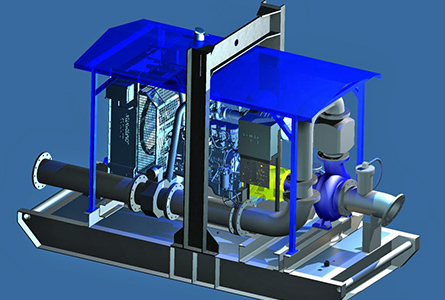

Diesel Driven Dewatering Pump Packages

Designed, engineered and manufactured at our facility in Perth, Western Australia our Diesel Driven dewatering packages are customised to suit specific project needs. Our in-house casting of all metals means we can provide competitive pricing and short lead times. We provide professional after-sales support with a large inventory of parts and assemblies available in a wide range of construction options, as well as consumable material options for high tensile fasteners, O-rings, oil seals and mechanical seals.

Build Features and Options

- Available as base frame mounted and/or heavy duty trailer mounted assemblies

- Engine options include Cummins, Caterpillar, Detroit

- Fuel Tank: Bunded fuel tank

- Control Panel: Engine manufacturer standard panel, or additionally client specified and/or telemetry can be fitted

- Bump Bar: Heavy duty rear bump bar

- Fuel Filling standard or optional

- Wiring: Mine spec or MDG15 available

- Pipework: Suction booms, discharge pipework to customer’s specifications

- Documentation packages

- Flowmeter

- Various material options available

Recent Projects

- Diesel Driven Water Pump Package For Pilbara Mine

- Delivering a Leading Mine Dewatering Pump System for WA Mine Site

Self-Priming Dewatering Pump Packages

Designed, engineered & manufactured at our facility in Perth, Western Australia our Diesel Driven dewatering packages are customised to suit specific project needs. Our in-house casting of all metals means we can provide competitive pricing and short lead times.

Build Features and Options

- Mounting options – trailer mounted, heavy duty base frames in materials to AS3679 – open direct mount, open skid type or skid type with fuel tank fitted.

- Engine configurations in both petrol and diesel models with performance and capacity to suit application from reputable OEM suppliers: – Caterpillar, Cummins, Perkins, Honda, Yanmar and Deutz.

- Major components manufactured from heavy section castings in materials to suit application.

- Highly durable rotating element designed using AS2837-316 stainless steel for shafts, sealed for life, re-grease able or oil fed long life bearings, DIN 24960 rubber bellows type mechanical seals with a variety of seat face options, both open and closed impeller designs available.

- Fasteners – 8.8 grade high tensile zinc coated and stainless steel 316 grade.

- Direct coupled units fitted with heavy duty pin bush or flexible tyre coupling fully enclosed in an anti-scatter guard.

- Pulley drive option features a heavy duty double row bearing fitted for overhung loading.

- Various material options available.