In 1950, students in Karlsruhe, Germany, founded Phyag KG and developed the first electrically operated drum pump – a response to the cumbersome hand pumps that were common at the time.

Their innovation, presented as “FLUX”, quickly attracted attention at trade fairs (Figure 1). At the same time, Ludwig Hahn from PROGRESS Verkauf GmbH was looking for a new industrial product that would complement his existing range of household appliances. He immediately recognised the market potential of the invention and acquired the shares in Phyag.

Product Innovation and Continuous Expansion of the Portfolio

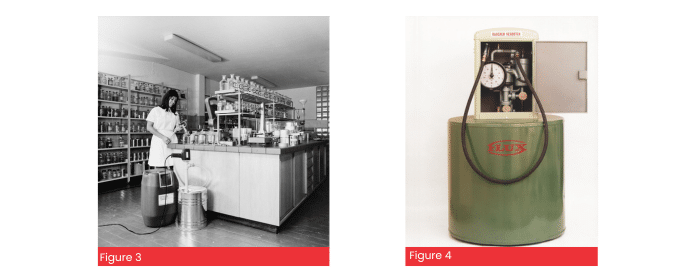

Just three years after the invention of the electric drum pump, an explosion-proof version followed in 1953 – a significant step for many branches of industry. The introduction of the FLUX 500 pump for viscous media – based on the eccentric screw principle – was another milestone (Figure 2). Thanks to this pump, it was possible to transfer viscous liquids for the first time. This was particularly important in the post-war period, when demand for a wide variety of chemical raw materials and their further processing rose rapidly.

Over the years, variants were developed for a wide range of operating ranges, such as pumps with two-stroke motors for mains-independent operation and laboratory pumps for small containers (Figure 3).

Customer requirements also prompted the development of flow meters, initially with analogue pointer displays and later, of course, in digital form (Figure 4). At the same time, the range of materials was expanded. The selection was always based on industry-specific requirements, whether in the chemical, pharmaceutical, food, or surface technology sectors. Materials such as polypropylene, PVDF, aluminium, stainless steel, and Hastelloy C were used to accommodate a wide variety of chemicals. On this basis, drum and container pumps were developed for numerous media – from low viscosity to viscous – and for a wide variety of drums, IBCs and other containers.

New Pump Technologies Are Being Added

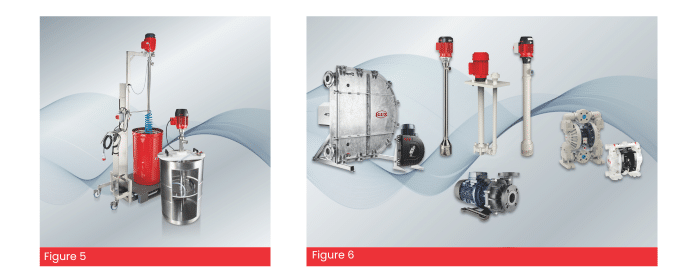

New pump technologies such as air-operated diaphragm pumps, magnetically coupled centrifugal pumps, centrifugal immersion pumps and – most recently – a new peristaltic pump series were gradually added (Figure 5). With the introduction of accumulator motors – such as the 300 series – FLUX also responded to the trend toward mobile energy supply. These products have received multiple design and technology awards for their innovative strength.

Complex applications such as the hygienic and ergonomic emptying of high-viscosity, non-flowable media from 200-litre drums were also addressed. Drum emptying systems such as VISCOFLUX lite (Ex) and VISCOFLUX mobile S illustrate the company’s transformation from a product manufacturer to a provider of integrated solutions tailored to the respective customer application

Practicality is always the focus: simple operation, tool-free disassembly, and quick cleaning are standard features today.

The production also developed dynamically: The site was relocated from Stuttgart-Botnang to Maulbronn, where the administration is also based today. All core components are still manufactured there – a clear commitment to quality and vertical integration “made in Germany”. At the same time, the company pushed ahead with its internationalisation. Subsidiaries in France, the USA, Benelux, Great Britain, India, and Thailand, as well as over 70 sales partners worldwide, make FLUX a globally positioned supplier of industrial pump technology today.

From Maulbronn to the World

The production also developed dynamically: The site was relocated from Stuttgart-Botnang to Maulbronn, where the administration is also based today. All core components are still manufactured there – a clear commitment to quality and vertical integration “made in Germany”. At the same time, the company pushed ahead with its internationalisation. Subsidiaries in France, the USA, Benelux, Great Britain, India, and Thailand, as well as over 70 sales partners worldwide, make FLUX a globally positioned supplier of industrial pump technology today.

FLUX pumps are in daily use worldwide, reliably operating by the thousands in the most challenging applications. Thanks to their exceptionally robust and durable design, they are also found in extraordinary environments – for example, at German research.

Applications That Set Standards

station in Antarctica, where they are used to refuel vehicles, or in an underground test mine 800 metres below the surface for repository technology.

They are even deployed at motor racing events, where precision and speed are essential. After 75 years, FLUX drum pumps are more popular than ever.

Proud to Partner With FLUX

At Malcolm Thompson Pumps, we’re proud to stand alongside FLUX in delivering world-class pumping technology to Australian industry. For 75 years, FLUX has set the benchmark in innovation, quality and reliability, values that align perfectly with our own.

See Flux in Action

Over the years, FLUX technology has powered countless operations across Australia.

Discover how our solutions are helping businesses boost performance and efficiency:

- Leading fruit company sees major benefits from new FLUX pump

- Nordon Cylinders halves maintenance time with FLUX technology

Talk to our team today to see how FLUX technology can power your operations forward, or click here to view our full range of FLUX products.